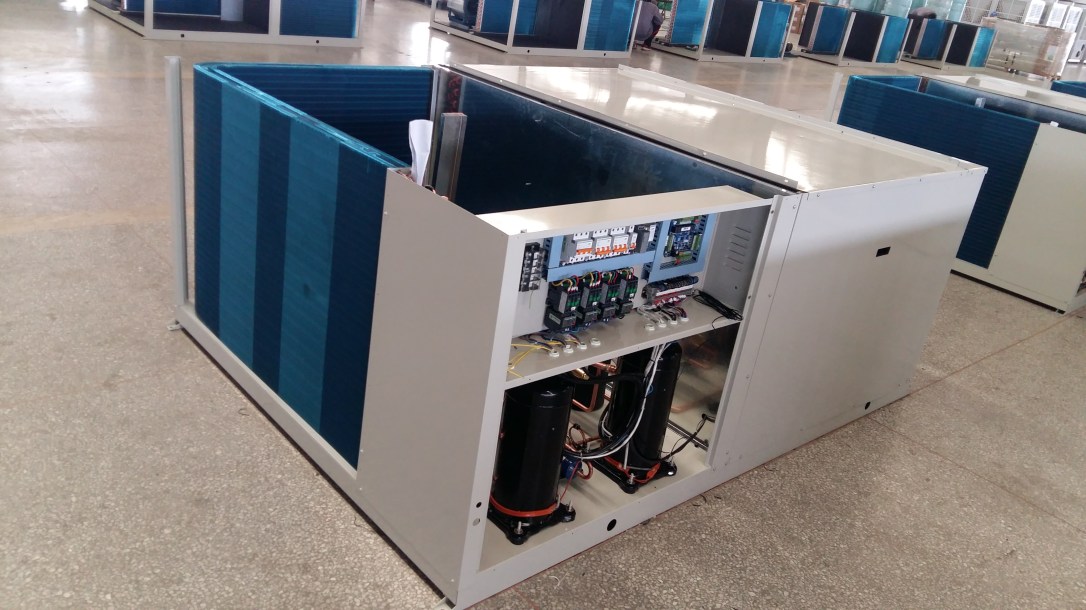

Components or Assembly Descriptions for DEKON rooftop air conditioner

A) Quiet operation. The packaged Rooftop series are basic constructed and engineered with noise reduction as a first

consideration, low noise mounted fans are used, 15mm wave type acoustic Insulation for compressor section and

compressors are mounted on vibration isolators.

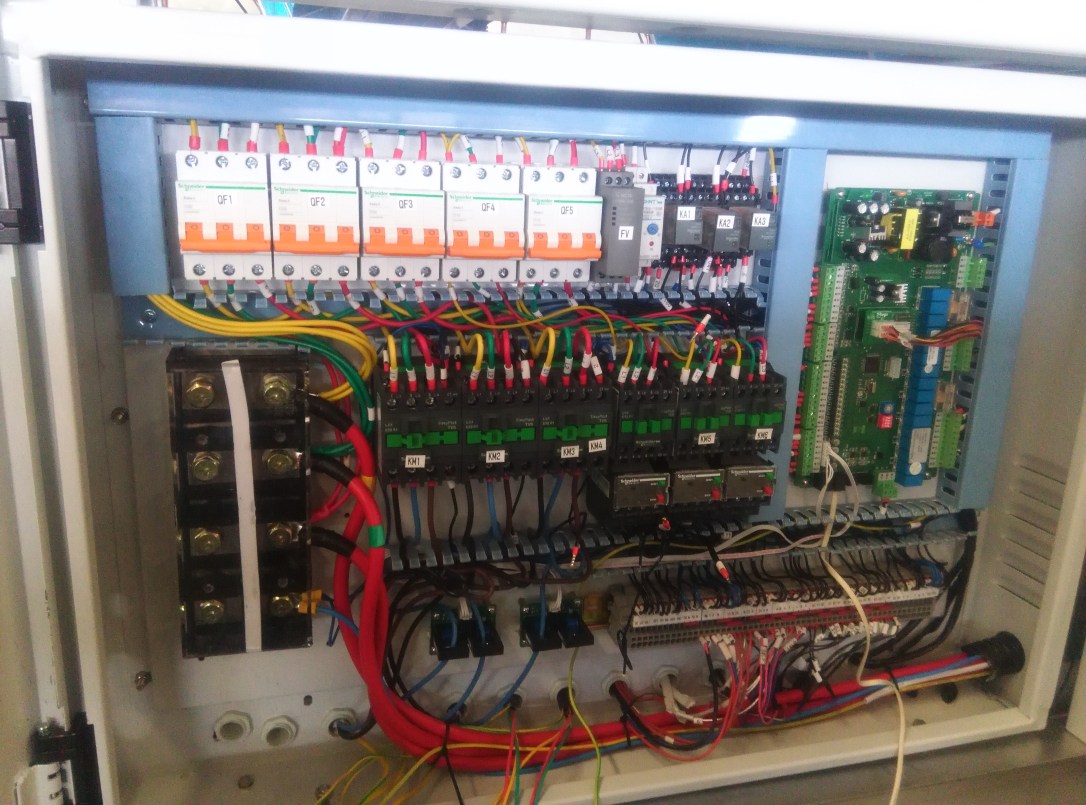

B) Low Cost Installation. Units are factory assembled and pre-charged, with a single point electrical connection. On arrival

to the job site they are ready to be lifted to their operating position through the lifting supports available on the units.

C) Capacities to Fit. There is a large production line of packaged units, with capacities ranging from 9.9 to 188.5kW for 50

Hz refrigeration tons at nominal conditions.

D) Casing. Heavy grade steel casing with polyester epoxy powder electrostatic oven-baked paint of coating finish, designed

for outdoor installation with 10mm insulation for evaporator section only. All units are provided with an 8mm thickness

aluminum frame filter that slides out or easy cleaning or replacement.

E) Compressor. The compressor used is hermetic refrigerant gas cooled, with internal thermal protection in each phase,

scroll type. The terminal boxes are rain tight, starting is direct-on-line. With high efficiency, low sound, so as to match all

other DEKON products’ reliability and efficiency.

F) Evaporator and Condenser Coils. The evaporator and condenser coils are designed to deliver their respective duties at

optimum performance at all design conditions. Coils are manufactured from seamless copper tubes mechanically expanded

into aluminum fins. All coils are tested at 30kg/cm2 (450 Psi) air pressure, under water to avoid leakage. They also

undergo dry chemical cleaning after manufacturing for optimum system cleanness.

G) Direct Driven Condenser Axial Fans. All condenser fans are of the axial type, which are directly mounted on the motor

shaft. All fans are selected for optimum efficiency and for maximum sound power reduction. Fan blades are made for

maximum corrosion resistance, and are statically and dynamically balanced before Installation. DEKON tries its bests to

WITH CE CERTIFICATE

4

ensure the low noise operation with high efficiency. All condenser fans are equipped with wire guards.

H) Condenser Fan Motor. All fans motors are of totally enclosed air-cooled, internal thermal current overload protected,

with class “IP56” electrical insulation.

I) Belt Drive Evaporator Fan. Fans are of the centrifugal type that is designed for maximum efficiency for uniform air

distribution. V-belt driven with variable pitch pulley as optional. All fans are statically and dynamically balanced to ensure

quiet operation and smooth performance.

J) Evaporator Fan Motors. Motors are of the totally enclosed induction type, with fan motor assembly placed on a floating

base with a flexible connection at the fan/casing interface. All fan motors of direct-driven are of the 3-speed type, highly

efficient induction type motors, totally enclosed air-cooled, squirrel-cage type, internal thermal current protected and with

class “B” insulation. Fan motors with V-belt-driven type are of 1 speed type.

K) Filters

All Models are provided with 8mm thickness aluminum frame filter (as standard features). Other filters are available upon

request.

L) Drain Pan

All units are provided with a drain pan having drain connection from one side. The drain pan is painted galvanized steel type

and insulated on the underside to prevent condensation.

M) Insulation

All units are internally lined with 10mm thermal insulation for coil and fan section (evaporator side only).

N) Easy Installation

The package rooftop has a compact design. It is supplied as a complete package ready for operation, with no extra controls

or other items to be installed. The units have a single power point entry with simple connections. All units are designed to

ensure maximum compliance with international standards.

Quick start-up is assured once installation is completed, as each rooftop unit is manufactured in an ISO9001:2000 listed

facility to guarantee quality. All units are tested at the factory to provide reliable start up.

NINGBO DEKON REFRIGERATION EQUIPMENT CO., LTD

Add:Air port logistic park, Ningbo,. P.R China

TEL: +86-574-88152763 FAX: +86-574-62131001

Mob1: +86-5356475680 Mob2:+86-13736095002

SKYPE:auxlsc5002